Maximize Efficiency, Minimize Waste

Revolutionize Your Oil Management with Oil Chef Solutions

Improve your fried foods while reducing your carbon impact with Oil Chef OCHPH oil saving device for up to 90 lb. fryers. This device boasts a maintenance-free design and requires no wires and no power. Plus, it's easy to install thanks to its self-installation system.

Reduced annual

cooking oil purchases

Reduced energy consumption

Reduced payroll

every month

Reduced food waste

Reduced waste

management

Carbon tax credits

Reduced

food cost

Growing food sales

These oil-saving devices reduce oil costs by up to 50% and provide energy savings for your business. Thanks to its formulation of silver and other rare and precious metals, these devices act as a catalysts on the cooking oil molecules, slowing down the oxidation and other deterioration processes. These devices stop the oil molecules from thickening and keep the oil in a thinner, finer form. These devices make the oil more efficient with heat transfer and conductivity, allowing you to fry your foods at a lower temperature without any additional cooking time.

In addition to oil savings, Oil Chef devices enhance heat conductivity, allowing food to cook at lower temperatures without compromising quality or speed. This reduction in frying temperatures directly translates into energy savings, cutting utility bills over time. With no power, wiring, or maintenance required, Oil Chef devices offer a seamless, cost-effective solution that starts generating ROI from day one.

Case Studies

Real-world examples of our impact

Independent laboratory efficacy testing

Frying Oil Lab Test Analysis

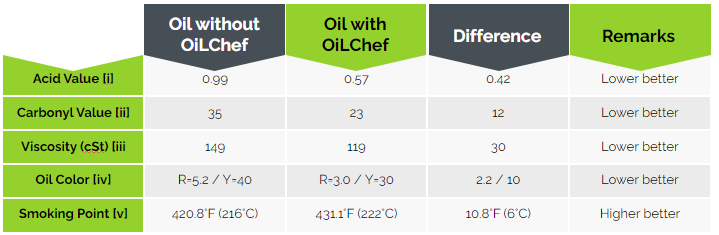

FRYING OIL DEGRADATION ANAYLYSIS DATA(Test Lab: Japan Food Research Laboratories)

-

NOTE

- The above data are based on samples of frying oil that have been in use for 8 hours a daily for three (3) consecutive days.

- Based on the standard test method of fat analysis (Japan Petrochemical Institute).

- Based on the standard test method of fat analysis (Japan Petrochemical Institute). Absorption of light is 1gram/sample with wavelength of 440nm.

- Viscosity was measured at 68°F (20°C) temperature.

- The oil color was gauged by use of Rovibond method (cell length: 10mm). R is Red and Y is Yellow.

- Based on the standard test method of fat analysis / Japan Petrochemical Institute.

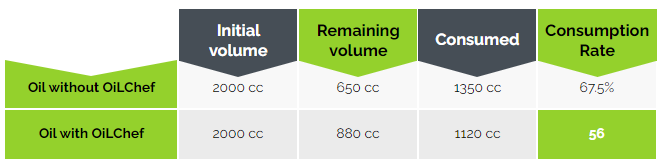

OIL CONSUMPTION TEST DATA(Test Lab: Aintech, Ltd. in Japan)

-

NOTE

- TESTING PERIOD: 8 hours daily for three (3) consecutive days.

- FRYING OIL & OBJECTS USED:

- Cooking Oil: 2 liters of Nissei frying oil.

- Coating powder for food objects: Showa tempura powder with chestnut starch powder.

- Food objects: Sweet-potato, potato, chicken meat, mackerel, pumpkin, ball onion, eggplant, and persimmon.

- TEMPERATURE SETTING:

- Temperatures were controlled within range of 302~356°F (160~180°C).

- Fixed average temperature below usual setting by 9~18°F (5~10°C) on average.

302-320°F - French fries, eggplants 320-338°F - Sweet potato, pork cutlet, Koroke (mashed potato pie) 338-366°F - Fish, shrimp, chicken

*Result Analysis: 11.5% (or 230 cc) less oil consumption on account of OiL Chef during the 3 days frying exercises.

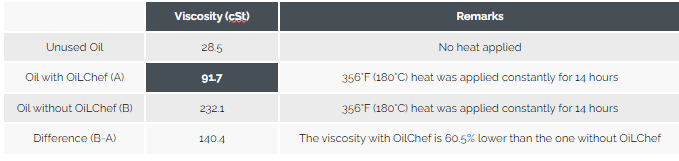

A SEPARATE KINETIC VISCOSITY TEST DATA (Test Lab: Nijuu Techui, Ltd. In Japan)

-

NOTE

- The viscosity was measured at 104°F (40°C) by Standard Oil Analysis Method using Canon Fenske Viscosity Gauge instrument.

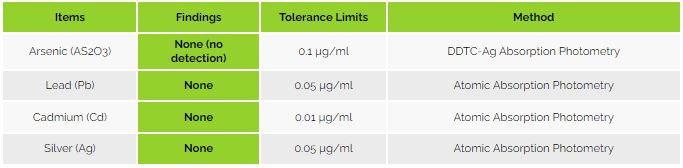

DISSOLUTION TEST DATA-SAFETY (Test Lab: Japan Food Research Laboratories)

-

NOTE

- For OiL Chef dissolution testing, 1 liter of frying oil as solvent was used and heated to 356°F (180°C) for 30 minutes.

Discover expert tips that restaurants worldwide use to reduce costs and improve food quality.

If you didn't get the email, let us know at salessupport@oilchef.com and we will get that to you right away!